The Kohler 7000 Series may experience low power due to issues such as a clogged carburetor or malfunctioning choke. Typical problems also include a lack of fuel or supply blockage.

Additionally, imbalanced or worn-out parts, loose bolts, or a damaged flywheel can contribute to the issues. To solve these problems, thorough inspection and maintenance are required. Regularly check the spark plug, air filter, and carburetor to ensure proper functioning, and address any issues promptly to prevent further complications.

The Kohler 7000 Series is equipped with powerful features, but like any other equipment, it may encounter problems. It is crucial to understand and address these issues to ensure optimal performance and longevity of the engine. By being aware of common problems and their potential causes, as well as implementing proactive maintenance measures, you can effectively manage and resolve any problems that may arise with the Kohler 7000 Series.

Credit: www.amazon.com

Common Problems With Kohler 7000 Series

The Kohler 7000 Series is a popular choice for homeowners and professionals alike. However, like any engine, it can experience some common problems that may affect its performance. Understanding these issues can help you diagnose and resolve any problems you may encounter.

No Or Low Power

One common issue with the Kohler 7000 Series is experiencing low power or even no power at all. This can be caused by a variety of factors, including imbalanced or worn-out parts, loose bolts, or a damaged flywheel. It can also be due to lack of fuel, which could be caused by issues such as being out of fuel, a supply blockage, fuel contamination, or injectors/carburetors not metering properly. If you are experiencing this problem, it is important to troubleshoot and identify the root cause to restore the engine’s power.

Hard Starting

Another common problem that users may encounter with the Kohler 7000 Series is hard starting. Engines that are hard to start may be getting too much fuel or not enough fuel, typically due to carburetor issues. A clogged carburetor can prevent the engine from receiving enough fuel, while a malfunctioning carburetor choke can cause the engine to receive too much fuel. Changing the spark plug and cleaning or replacing the carburetor can help address this issue.

Engine Stalling

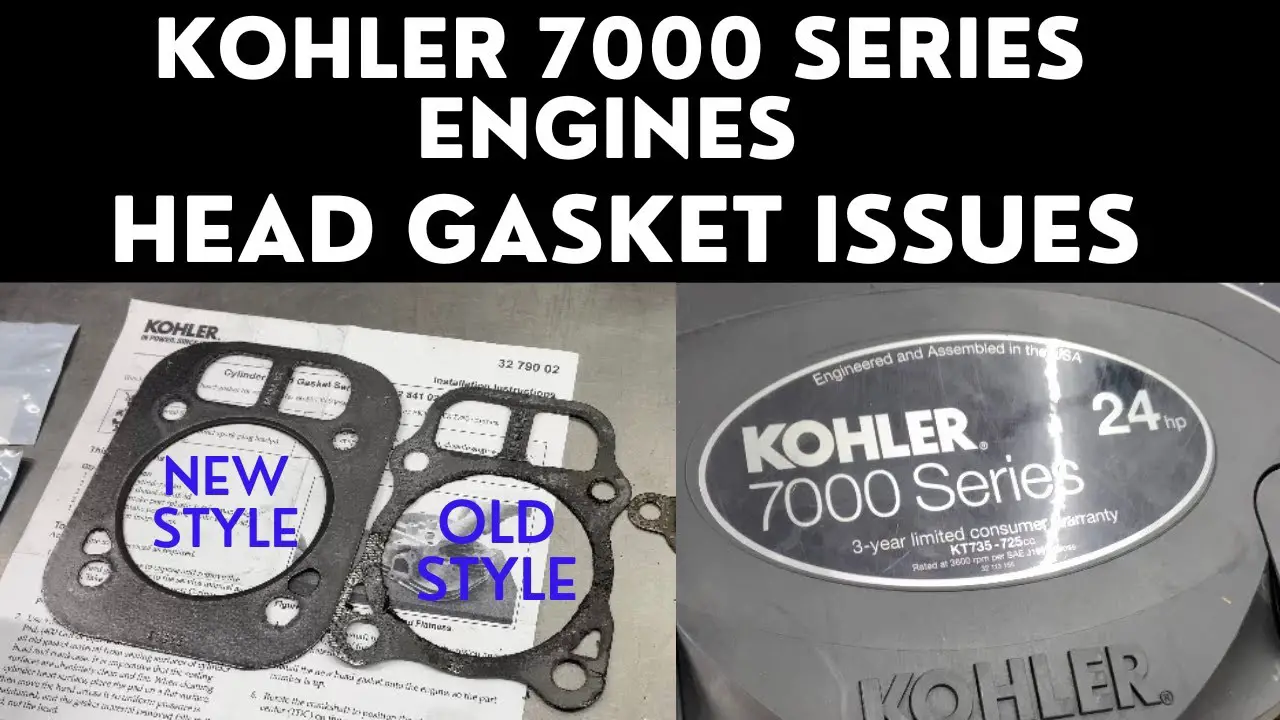

One frustrating problem that users may encounter is engine stalling. This can be concerning, as it may affect the engine’s reliability and performance. Engine stalling can be caused by a variety of issues, including exhaust gap, blown head gasket, or malfunctioning throttle cable. Identifying the specific cause of the stalling can help in implementing the necessary repairs or adjustments to prevent future occurrences.

Credit: m.youtube.com

Diagnosing And Repairing Kohler 7000 Series Issues

Kohler 7000 Series engines are known for their power and reliability. However, like any machine, they may experience issues over time. Understanding how to diagnose and repair common problems can help keep your Kohler engine running smoothly for years to come.

Checking The Oil

Regularly check the oil level in your Kohler 7000 Series engine to ensure it is within the recommended range. Low oil levels can lead to engine damage and reduced performance.

Inspecting The Spark Plug Wire

Inspect the spark plug wire for signs of wear or damage. A faulty spark plug wire can cause the engine to misfire or run unevenly.

Examining The Throttle Bracket

Examine the throttle bracket to ensure it is properly adjusted and functioning. A malfunctioning throttle bracket can affect the engine’s speed and responsiveness.

Removing The Valve Cover

Remove the valve cover to inspect the valves and ensure they are operating smoothly. This can prevent issues related to valve clearance and performance.

Adjusting The Exhaust Gap

Adjust the exhaust gap according to the manufacturer’s specifications. Improper gap adjustment can lead to decreased engine efficiency and power.

Identifying A Blown Head Gasket

Look for signs of a blown head gasket such as coolant leakage or white smoke from the exhaust. A blown head gasket can cause overheating and loss of power.

Replacing The Head Gasket

If a blown head gasket is identified, it is crucial to replace it promptly to prevent further engine damage and restore optimal performance.

Installing The Rocker Arms And Exhaust Push Rod

Assure that the rocker arms and exhaust push rod are properly installed and adjusted to maintain proper valve operation and engine performance.

Reattaching The Throttle Cable

When necessary, reattach the throttle cable securely to ensure smooth and responsive throttle control.

Replacing The Air Filter

Regularly replace the air filter to prevent dirt and debris from entering the engine, which can lead to reduced performance and premature wear.

Understanding Spark Plug Options

Choosing the right spark plug for your Kohler 7000 Series engine is crucial. Consider the manufacturer’s recommendations and engine requirements for optimal performance.

Selecting The Right Air Filter

When selecting an air filter, ensure it is compatible with your Kohler 7000 Series engine and meets the necessary filtration requirements for optimal engine protection.

Considering Carburetor Fixes

If encountering carburetor issues, consider appropriate carburetor fixes to maintain proper fuel-air mixture and ensure smooth engine operation.

Recalls And Lifespan Of Kohler Engines

When it comes to purchasing a lawnmower with a reliable engine, Kohler is a brand that often comes to mind. However, like any other brand, Kohler engines are not immune to problems. In this article, we will explore the recalls that have affected Kohler engines and also discuss the average lifespan of these engines.

Recall Information

Just like any other manufacturer, Kohler has had its fair share of recalls over the years. These recalls are essential to ensure the safety and long-term performance of their engines. If you own a Kohler engine or are looking to purchase one, it’s crucial to stay informed about these recalls to address any potential issues promptly.

Unfortunately, specific details on recalls for the Kohler 7000 Series are limited. Kohler has not provided explicit information regarding recalls for this particular series. However, it is always a good practice to regularly check with Kohler’s official website or contact their customer support for the most up-to-date recall information.

Lifespan Of Kohler Lawn Mower Engines

Kohler engines are known for their durability and long lifespan. On average, a properly maintained Kohler lawn mower engine can last between 1,500 to 2,000 hours of use. This estimate can vary depending on factors such as maintenance schedule, usage conditions, and engine model.

To ensure your Kohler engine performs optimally throughout its lifespan, regular maintenance is essential. This includes regular oil changes, air filter replacements, spark plug inspections, and cleaning of the carburetor. Proper maintenance will not only extend the engine’s life but also improve its overall performance and fuel efficiency.

Average Lifespan Of Kohler K Series Engines

The Kohler K Series engines have gained a reputation for their reliability and longevity. These engines are commonly found in various equipment, including lawn tractors, garden tractors, and commercial mowers. On average, a well-maintained Kohler K Series engine can last between 1,500 to 2,500 hours of use.

However, it’s important to note that the lifespan of any engine can vary depending on several factors. Factors such as regular maintenance, proper usage, and the quality of fuel and oil used can significantly influence the longevity of the engine.

In conclusion, while Kohler engines are known for their durability and long lifespan, it is crucial to stay informed about potential recalls and practice regular maintenance to keep the engines running smoothly for years to come.

Credit: mowing.expert

Troubleshooting Kohler 7000 Series Engines

If your Kohler 7000 Series engine is experiencing issues, troubleshooting may be required to address various problems. Common concerns such as low power output or starting difficulties can be resolved by checking spark plugs, carburetors, and fuel supply for optimal performance.

Regular maintenance and proper diagnosis play key roles in ensuring the engine’s longevity and efficiency.

Identifying Common Problems

Some common problems that may arise with Kohler 7000 Series engines include lack of power, starting issues, and abnormal engine noises.

Potential Causes

The potential causes of these issues could range from fuel system problems to spark plug issues or dirty air filters.

Steps To Troubleshoot

When troubleshooting a Kohler 7000 Series engine, follow these steps to address the problems effectively:

- Check the fuel levels in the tank.

- Inspect the spark plugs for any signs of damage.

- Clean or replace air filters if necessary.

- Ensure the carburetor is functioning properly.

- Inspect the fuel lines for any blockages.

- Check the ignition system for any malfunctions.

Frequently Asked Questions Of Kohler 7000 Series Problems

What Is The Recall On Kohler Engines?

The recall on Kohler engines refers to a specific issue identified in some engine models. It is important to contact Kohler directly to get accurate and up-to-date information regarding any recalls.

What Is The Difference Between Kohler 7000 And 7000 Pro?

The Kohler 7000 Pro has a commercial-grade air filtration system, while the Kohler 7000 does not.

How Many Hours Will A Kohler Lawn Mower Engine Last?

A Kohler lawn mower engine can last from 800 to 2,000 hours with regular maintenance.

Conclusion

To troubleshoot the Kohler 7000 Series problems, it’s important to address the underlying causes of low power. From checking the oil and valve cover to inspecting the throttle bracket and exhaust gap, each step plays a crucial role in resolving the issue.

Additionally, factors like blown head gaskets and improper carburetor functioning can affect the power output. By following these steps and utilizing the appropriate parts like Kohler spark plugs and air filters, you can significantly improve the performance and lifespan of your Kohler engine.

Keep these tips in mind and enjoy a smoothly running engine for years to come.