To set a torque wrench, adjust the dial at the bottom handle to the desired force and then tighten the bolt until you feel the wrench click or ‘slip’. Proper use and maintenance of a torque wrench are crucial in ensuring accurate torque specifications for nuts and bolts.

Several video tutorials demonstrate proper torque wrench usage, including setting the torque, handling extensions, obtaining torque specs, and taking care of the equipment. Understanding how to accurately set a torque wrench is essential for various mechanical applications, ensuring proper fastening and preventing damage from over-tightening.

The adjustment process is straightforward, but it is crucial to follow the specific guidelines for each torque wrench model. Whether it’s for industrial or DIY projects, mastering the proper settings of a torque wrench is vital for achieving precise and uniform torque in mechanical assemblies.

How To Set Torque Wrench

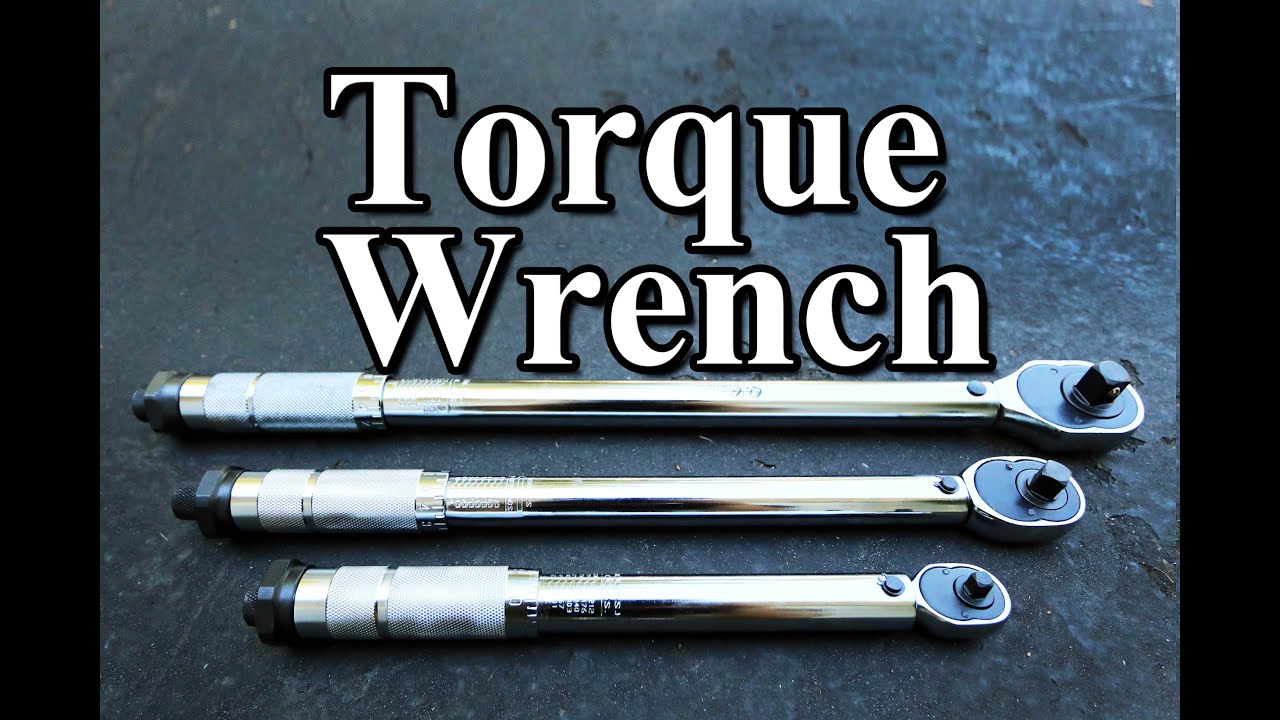

A torque wrench is an essential tool for any mechanic or DIY enthusiast. Knowing how to set and use a torque wrench correctly is crucial for ensuring that nuts and bolts are tightened to the exact specification. In this article, we will discuss the adjustments and calibration, as well as the process of setting the torque on a torque wrench.

Adjustments And Calibration

Before using a torque wrench, it’s crucial to ensure that it is properly calibrated and adjusted. Here are the steps to make adjustments and calibrate your torque wrench:

- Pull out the dial at the bottom part of the handle.

- Rotate the dial to calibrate it to the desired torque value in accordance with the specific torque specification.

- Keep in mind that over time, a torque wrench may require recalibration, and it’s recommended to perform periodic calibration checks to maintain accuracy.

Setting The Torque

Setting the torque on a torque wrench involves adjusting it to the desired torque level at which the fastener needs to be tightened. The following steps outline the process of setting the torque:

- Pull out the dial at the bottom part of the handle.

- Rotate the dial to the degree of force you want to exert on the bolt according to the specific torque specification.

- Begin tightening the bolt, and stop tightening when you feel the wrench click or ‘slip’, indicating that the desired torque has been reached.

By following the correct procedure for adjustments, calibration, and setting the torque on a torque wrench, you can ensure precise and accurate fastening, ultimately contributing to the safety and integrity of your mechanical work.

Credit: m.youtube.com

Importance Of Proper Torque Settings

The importance of setting torque wrench video cannot be overstated when it comes to ensuring the safety and integrity of construction and automotive projects. Achieving the proper torque settings is crucial for preventing damage to materials and equipment, as well as ensuring the long-term functionality of the assembled parts.

Preventing Overtightening

Overtightening can lead to stripped threads, sheared bolts, or damaged components, compromising the structural integrity of the assembly. By setting the torque wrench to the specified level, you can mitigate the risk of overtightening and avoid costly repairs and replacements.

Avoiding Under-tightening

Conversely, under-tightening can result in loose connections, leaks, or inadequate clamping force, ultimately leading to performance and safety issues. By ensuring the torque settings are accurate, you can prevent under-tightening and maintain the reliability of the assembly.

Common Mistakes And How To Avoid Them

When using a torque wrench, it’s crucial to be aware of common mistakes that can affect the tool’s accuracy. By understanding these errors and how to prevent them, you can ensure precise torque application for your projects.

Using Incorrect Extensions

One common mistake is using incorrect extensions with your torque wrench. Avoid using extensions that are too long or too short, as they can affect the applied torque. Opt for extensions recommended by the manufacturer to maintain accuracy.

Ignoring Torque Wrench Maintenance

Another crucial error is ignoring torque wrench maintenance. Regularly check and calibrate your torque wrench to ensure it remains accurate. Over time, torque wrenches can drift out of calibration, leading to incorrect torque values.

Credit: www.amazon.com

Tips For Using Torque Wrench Effectively

When it comes to tightening bolts accurately, a torque wrench is an indispensable tool. However, using a torque wrench effectively requires proper understanding and technique. In this section, we will discuss some essential tips that will help you optimize your torque wrench usage and ensure accurate bolt tightening.

Understanding Torque Specs

Before using a torque wrench, it is crucial to understand the torque specifications provided by the manufacturer. Torque specs determine the amount of force required to tighten a specific bolt to ensure optimal performance and safety. These specs are usually expressed in foot-pounds (ft-lbs), Newton meters (Nm), or inch-pounds (in-lbs).

When using a torque wrench, always match the torque specs provided by the manufacturer for the particular bolt you are working on. Using the incorrect torque value can lead to under or over-tightening, which can result in bolt failure or damage to the component being secured. Ensure you have the right torque conversion chart or tool to convert between different torque units.

Proper Order Of Tightening Bolts

In certain applications, it is important to follow a specific order when tightening multiple bolts. This is especially true for components with gaskets or when securing critical assemblies. Following the proper bolt tightening sequence helps distribute the load evenly and ensures proper sealing and alignment.

Consult the manufacturer’s instructions or service manual to identify the correct tightening sequence for your specific application. By adhering to the recommended order, you can prevent uneven stress distribution and potential leaks or component misalignment.

Calibrating And Maintaining Your Torque Wrench

To ensure the accuracy and reliability of your torque wrench, regular calibration and maintenance are essential. Over time, these tools can lose their accuracy or suffer from wear and tear. Regularly calibrating your torque wrench helps ensure it provides precise readings for optimal bolt tightening.

Additionally, regular maintenance such as cleaning and lubrication keeps your torque wrench in optimal working condition. Follow the manufacturer’s recommendations regarding maintenance intervals and techniques to maximize the lifespan and accuracy of your torque wrench.

- Calibrate your torque wrench regularly to ensure accuracy

- Clean and lubricate your torque wrench according to manufacturer guidelines

- Store your torque wrench in a clean, dry place to prevent damage

By following these tips, you can effectively use a torque wrench with confidence and precision. Understanding torque specs, using the proper order of tightening bolts, and maintaining your torque wrench will help you achieve accurate and reliable results in your mechanical projects.

Credit: www.youtube.com

Frequently Asked Questions For Setting Torque Wrench Video

How Do I Set My Torque Wrench?

To set your torque wrench, follow these steps: 1. Adjust the torque wrench by pulling out the dial at the bottom handle and rotating it to the desired force. 2. Begin tightening the bolt and stop when you feel the wrench click or ‘slip’.

3. Remember to always pull, not push, to apply torque. 4. Adjust your stance to prevent falling. 5. Practice proper torque wrench safety and usage.

How Do You Set Torque Settings?

Adjust torque settings by pulling the dial on the handle, rotate to desired force level. Tighten the bolt until you feel a click or slip.

Can I Calibrate My Torque Wrench At Home?

Yes, you can calibrate your torque wrench at home by adjusting the settings as needed.

Conclusion

Ensure precise torque settings by following the proper techniques, adjusting the wrench accurately. Master the art of setting torque for optimal performance and efficiency. Remember, a calibrated torque wrench is the key to success in all your bolt-tightening endeavors. Happy torquing!