The lawn mower ignition coil kill wire connects to the ignition coil and is responsible for shutting off the engine. It plays a crucial role in stopping the engine when needed, and it is essential for the proper functioning of the lawn mower.

The ignition coil kill wire is a critical component in the electrical system of a lawn mower. This wire is responsible for stopping the engine when necessary, and it connects to the ignition coil. Understanding the role and functioning of the kill wire is essential for maintaining and troubleshooting lawn mower engines.

By grasping the intricacies of this component, individuals can effectively diagnose and address issues related to engine shutdown. In this comprehensive guide, we’ll delve into the workings of the lawn mower ignition coil kill wire, its importance, and how to identify potential problems with it.

Credit: m.youtube.com

Understanding Lawn Mower Ignition Coil Kill Wire

When it comes to understanding how your lawn mower’s ignition system works, it’s important to take a closer look at the kill wire connected to the ignition coil. The ignition coil is an essential component responsible for generating the high-voltage current needed to create a spark and ignite the fuel mixture in the engine. But what exactly does the kill wire do and why is it significant in the overall functioning of your lawn mower?

Exploring The Significance Of The Kill Wire

The kill wire, also known as the stop wire, is a crucial element in the lawn mower’s electrical system. Its main purpose is to interrupt the flow of electricity from the ignition coil to the spark plugs, effectively stopping the engine. This is important for various reasons, such as performing maintenance or repairs on the lawn mower, ensuring the safety of the user, and preventing accidental starts.

By connecting the kill wire to the ignition coil, you can easily control when and how your lawn mower starts and stops. When the switch or control mechanism connected to the kill wire is activated, it sends a signal to the ignition coil to cut off the spark, stopping the engine instantly.

Connecting A Kill Switch Directly To The Ignition Coil

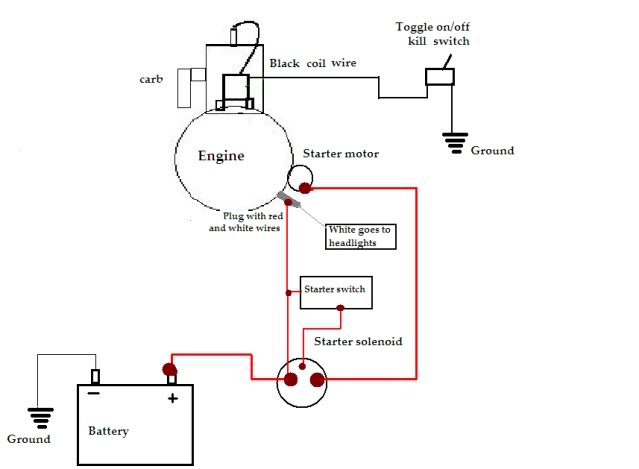

To further enhance the convenience and control over your lawn mower’s engine, you can connect a kill switch directly to the ignition coil. This allows you to have easy access to a dedicated switch or button that can instantly stop the engine whenever necessary. By wiring the kill switch to the kill wire on the ignition coil, you can effectively turn off the engine with a simple flick of the switch.

This direct connection ensures that the kill switch has a direct control over the ignition coil, providing a reliable and efficient way to stop the engine when needed. It eliminates the need for additional wiring or complicated circuitry, making it a straightforward process to implement.

In conclusion, understanding the lawn mower ignition coil kill wire is crucial for maintaining the safety and control of your lawn mower’s engine. By exploring its significance and connecting a kill switch directly to the ignition coil, you can enjoy the convenience and peace of mind that comes with having full control over the starting and stopping of your lawn mower.

How The Ignition Coil Electrical System Works

The Lawn Mower Ignition Coil Kill Wire is a crucial component that helps stop the engine. When the stop switch is activated, it interrupts the flow of electrons to the spark plug, preventing the engine from running. This simple yet essential mechanism ensures the efficient functioning of the ignition system in lawn mowers.

Copper And Its Properties

Copper is a highly conductive metal that forms the basis of the electrical system in many lawnmower engines. Its exceptional conductivity allows for the efficient transmission of electrical current within the ignition coil system.

Electrical Current In Lawnmower Engines

The electrical system in a lawnmower engine consists of an ignition coil that generates high voltage electricity to ignite the air-fuel mixture in the combustion chamber, leading to the engine’s operation. This coil operates using the principles of electromagnetic induction, converting low voltage from the lawnmower’s battery into the high voltage required for spark plug ignition.

Insight Into Turning Off A Lawnmower Engine

When it’s time to turn off a lawnmower engine, the kill wire comes into play. This wire disrupts the ignition coil’s normal operation, stopping the flow of electricity to the spark plug and halting the engine’s combustion process.

Understanding The Functionality Of The Stop Wire

The stop wire, also known as the kill wire, coordinates with the ignition system to break the electrical circuit and stop the engine. This simple yet crucial component ensures safe, efficient engine shutdown when needed.

Testing The Kill Wire For Efficiency

Ensuring the effectiveness of the kill wire is vital for proper engine function and safety. Using a multimeter or continuity tester, the kill wire can be tested to verify that it interrupts the electrical circuit effectively, preventing the flow of electricity to the spark plug when the engine needs to be shut down.

Troubleshooting And Maintenance

The kill wire on the lawn mower ignition coil is responsible for shutting off the engine. It is important to troubleshoot and maintain this wire to ensure proper functionality of the ignition coil and overall performance of the lawn mower.

What To Do When V-twin Briggs Won’t Shut Off

If your V-Twin Briggs won’t shut off, it could be due to a faulty kill wire or diode. Check for any visible damage or wearing on the kill wire and diode. Make sure the connections are secure and not corroded. If everything looks fine, proceed to test the kill wire and diode using a multimeter.

Replacing A Faulty Kill Wire Diode

If testing reveals a faulty diode, it’s crucial to replace it promptly. A faulty diode can prevent the ignition system from properly shutting off the engine, leading to potential safety hazards. Look for a replacement diode that matches the specifications of your lawn mower’s ignition system to ensure proper functionality.

Identifying Faults In The Kill/stop Wire

Inspect the kill/stop wire for any signs of damage, such as fraying or exposed wiring. Additionally, check for loose or disconnected connections at the ignition coil and the kill switch. It’s essential to address any faults promptly to prevent issues with engine shutdown and overall performance.

Testing For Electrical Shorts With A Multimeter

Use a multimeter to test for electrical shorts in the kill wire. Set the multimeter to the continuity setting and check for any unexpected connections or disruptions in the wire. This will help identify potential issues that could affect the proper functioning of the ignition coil kill wire.

Credit: maker.pro

Understanding The Components

The lawn mower ignition coil kill wire is an integral component that effectively stops the engine. It plays a crucial role in redirecting electron flow to shut down the mower engine. With the stop wire’s functioning and testing methods explained, understanding its significance becomes easier.

Briggs And Stratton Ignition Coil

The Briggs and Stratton ignition coil is a vital component of the lawn mower electrical system. It is responsible for generating and amplifying the electrical current needed to produce a spark in the spark plug, which in turn ignites the fuel-air mixture in the engine. This ignition coil is designed specifically for Briggs and Stratton engines, ensuring optimal performance and compatibility. By using a high-quality ignition coil like the Briggs and Stratton, you can rest assured that your lawn mower will start reliably and run smoothly.Oakten Ignition Coil For Briggs & Stratton

For those looking for a reliable and affordable alternative to the original Briggs and Stratton ignition coil, the Oakten ignition coil is an excellent choice. Designed to fit Briggs and Stratton engines, this ignition coil offers comparable performance at a more budget-friendly price. With its durable construction and precise engineering, the Oakten ignition coil ensures consistent ignition, allowing your lawn mower to operate at its best. Upgrade your lawn mower’s ignition system with the Oakten ignition coil for reliable starts and smooth performance.Oakten Ignition Coil For Improved Performance

If you’re seeking improved performance from your lawn mower, consider upgrading to the Oakten ignition coil. This ignition coil is specially designed to enhance the spark plug’s firing efficiency, resulting in improved combustion and power delivery. With a stronger and more consistent spark, your lawn mower will experience smoother acceleration, better fuel efficiency, and reduced emissions. Experience the difference in performance with the Oakten ignition coil and take your lawn mowing experience to the next level. In conclusion, understanding the components of a lawn mower’s electrical system, such as the Briggs and Stratton ignition coil and the Oakten ignition coil, can help you make informed decisions when it comes to maintaining and upgrading your lawn mower. Choosing a high-quality ignition coil ensures reliable starts, smooth operation, and improved performance. Upgrade your lawn mower’s ignition system, enhance its reliability, and enjoy a more efficient mowing experience with the right ignition coil.Answering Common Questions

The lawn mower’s ignition coil kill wire functions as a safety mechanism to shut off the engine. Connected to the ignition coil, it interrupts the electrical current flow to stop the engine. Understanding its role ensures proper functioning and helps troubleshoot potential issues with the mower’s electrical system.

Functionality Of The Kill Wire On The Ignition Coil

The kill wire on the ignition coil is a crucial component that is responsible for shutting down the engine by stopping the flow of electricity to the spark plug.

Importance Of The Wire Connecting To The Ignition Coil

The wire connecting to the ignition coil is essential as it delivers high voltage current to the spark plug, which is necessary for igniting the fuel mixture in the engine.

Identifying A Faulty Lawn Mower Ignition Coil

To identify a faulty ignition coil, you can perform a continuity test using a multimeter to check for any breaks in the circuit that may prevent the spark plug from receiving the required voltage.

Credit: www.atltf.com

Frequently Asked Questions For Lawn Mower Ignition Coil Kill Wire

What Does The Kill Wire Do On The Ignition Coil?

The kill wire on the ignition coil is a wire that connects to the mower harness and is used to stop the engine. When the kill switch is activated or the ignition switch is turned off, the kill wire is grounded, which stops the flow of electricity to the ignition coil and shuts off the engine.

What Is The Wire That Connects To The Ignition Coil?

The wire that connects to the ignition coil is called an ignition cable or spark plug wire. This wire delivers high voltage current to the spark plugs, igniting the fuel mixture in the engine.

How Do I Know If My Lawn Mower Ignition Coil Is Bad?

To check if your lawn mower ignition coil is bad, disconnect the kill wire and measure ohms to ground – open circuit for when the engine should run and connected when it should stop.

Conclusion

To summarize, the lawn mower ignition coil kill wire plays a crucial role in the electrical system of the engine. It is responsible for stopping the engine by interrupting the flow of current to the spark plug. Understanding the function and testing the kill wire can help diagnose engine issues and ensure proper functioning.

If you’re experiencing problems with your ignition coil, it’s essential to consider replacing it with a high-quality, compatible one to maintain the performance of your lawn mower.