If your Briggs and Stratton engine is experiencing timing problems, you can adjust the timing using a timing light and wrenches. This process ensures proper engine performance and can be done with tools available at most auto or lawn mower parts stores.

Storing equipment with untreated fuel can lead to engine damage, causing it to not start or run correctly, while issues with the ignition timing are often due to a sheared flywheel key. When facing surging engine performance or no spark, it’s crucial to inspect the ignition system and timing to identify and repair any problems.

Ensuring proper timing is critical for the efficient operation of a Briggs and Stratton engine. If you encounter timing issues with your engine, it’s imperative to address them promptly to avoid potential damage and ensure optimal performance. Whether it’s adjusting the timing using a timing light and tools or troubleshooting ignition system problems, understanding the causes and solutions for timing issues is essential for maintaining the functionality of your Briggs and Stratton engine. This article aims to provide comprehensive insights into diagnosing and resolving timing problems with Briggs and Stratton engines, so you can keep your equipment running smoothly and effectively.

Credit: www.briggsandstratton.com

Common Issues With Briggs And Stratton Timing

Briggs and Stratton engines are renowned for their reliability and performance. However, like any mechanical system, they can experience issues over time. One common problem that owners may encounter is timing problems. The timing of the engine is crucial for its proper functioning and any issues with it can affect the engine’s performance and reliability. In this article, we will discuss the common symptoms and causes of timing problems in Briggs and Stratton engines.

Symptoms Of Timing Problems

Identifying the symptoms of timing problems in a Briggs and Stratton engine is essential for prompt troubleshooting and solution. Here are some common signs that indicate possible timing issues:

- Difficulty starting the engine or engine not starting at all

- Engine misfires or backfires

- Reduced power and performance

- Inconsistent or uneven engine operation

- Excessive vibration or unusual noises from the engine

If you notice any of these symptoms, it is important to address the timing problem promptly to avoid further damage to the engine.

Causes Of Timing Problems

Understanding the causes of timing problems in Briggs and Stratton engines is crucial for effective troubleshooting. Here are some common factors that can lead to timing issues:

- Worn or damaged timing belts or chains

- Incorrect installation or alignment of timing components

- Slipped or damaged timing gears

- Malfunctioning ignition system or ignition timing

- Engine overheating or excessive wear

Regular maintenance, including timely replacement of worn parts and proper installation of timing components, can help prevent timing problems in Briggs and Stratton engines.

In conclusion, timing problems in Briggs and Stratton engines can cause various issues, affecting the engine’s performance and reliability. By being aware of the symptoms and causes of timing issues, owners can promptly address any problems and ensure their engines operate smoothly. Regular maintenance and proper installation of timing components are crucial for preventing timing problems and prolonging the life of Briggs and Stratton engines.

Credit: m.youtube.com

How To Align Briggs & Stratton Engine Timing Gears

Briggs & Stratton engines are renowned for their reliability and performance. However, occasional timing issues can occur, affecting the engine’s operation. Properly aligning the timing gears is crucial to ensure smooth engine performance and prevent costly damage. In this guide, we’ll walk you through the process of aligning Briggs & Stratton engine timing gears, enabling you to tackle this essential task with confidence.

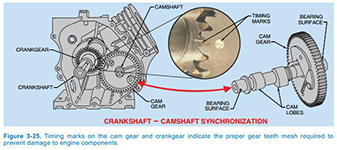

Checking Timing Marks

Before beginning the alignment process, it’s essential to check the timing marks on the engine. Locate the timing marks on both the crankshaft and camshaft gears to ensure they are aligned correctly. Use a timing light and a set of wrenches to adjust the timing if needed.

Camshaft And Camshaft Timing Gear Alignment

Aligning the camshaft and camshaft timing gear is critical for proper engine operation. Start by removing the valve cover to access the camshaft. With the piston at top dead center (TDC) and the timing marks aligned, ensure the camshaft timing gear is positioned accurately. Carefully examine the alignment to confirm that the camshaft and timing gear are perfectly synchronized.

Adjusting Timing On Briggs And Stratton Engine

Adjusting the timing on a Briggs and Stratton engine can be done with a timing light and wrenches. Keep your engine running smoothly by aligning timing marks correctly and checking camshaft gear alignment. Prevent issues like surging or starting problems with proper timing adjustments.

Using A Timing Light

To adjust the timing on a Briggs and Stratton engine, you can use a timing light. Ensure that the engine is off and the key is removed before proceeding.Tools Required For Timing Adjustment

The following tools are required for adjusting the timing on a Briggs and Stratton engine: – Timing light – Wrenches – Set of screwdrivers When adjusting the timing, it’s essential to take precautionary measures to prevent injury. Always refer to the user manual for specific instructions related to your engine model. Can you adjust the timing on a Briggs and Stratton engine? It’s possible to adjust your engine’s timing with a timing light and a set of wrenches, tools available at any auto or lawn mower parts store. What is the most common reason why a Briggs & Stratton small engine won’t run correctly? Stale fuel, dirt, and debris are the most common cause of outdoor power equipment not starting or running properly. If you store equipment with untreated gas in the tank, it can lead to engine damage.Troubleshooting Ignition System Problems

If your Briggs and Stratton engine is experiencing timing problems, it can lead to issues with the ignition system. The ignition system is responsible for creating the spark needed to ignite the fuel mixture in the engine. When the timing is off, it can prevent the spark from occurring at the right time, resulting in difficulties starting the engine or poor performance.

Testing For Sheared Flywheel Key

One common cause of timing problems in Briggs and Stratton engines is a sheared flywheel key. The flywheel key is a small metal piece that connects the flywheel to the crankshaft. It ensures that the flywheel and crankshaft rotate together and stay in sync. However, if the flywheel key becomes damaged or sheared, it can throw off the timing of the ignition system.

To test for a sheared flywheel key, follow these steps:

- Disconnect the spark plug wire and remove the spark plug.

- Use a socket wrench to remove the nut holding the flywheel in place.

- Gently pry the flywheel off the crankshaft using a flywheel puller tool.

- Inspect the flywheel key for any signs of damage or shearing. If the key is broken or worn out, it will need to be replaced.

Checking Flywheel Magnets For Issues

Another potential cause of timing problems is issues with the flywheel magnets. The magnets are responsible for creating the magnetic field that triggers the ignition spark. If the magnets become weak or damaged, they may not generate enough magnetic force to create a spark at the right time.

To check the flywheel magnets, follow these steps:

- Disconnect the spark plug wire and remove the spark plug.

- Use a socket wrench to remove the nut holding the flywheel in place.

- Inspect the flywheel magnets for any signs of damage, such as cracks or chips.

- If the magnets appear weak or damaged, they will need to be replaced.

By testing for a sheared flywheel key and checking the flywheel magnets for issues, you can troubleshoot and resolve timing problems in your Briggs and Stratton engine. Ensuring proper timing is essential for optimal ignition system performance and overall engine functionality.

Preventing Timing-related Issues

Learn how to prevent timing-related issues with Briggs and Stratton engines. Avoid potential problems with timing gears and camshafts by aligning the timing marks correctly. Adjusting the engine timing with the necessary tools can help ensure smooth operation.

Regular Maintenance Practices

Regular maintenance is crucial to prevent timing-related issues in Briggs and Stratton engines.

- Change oil and replace filters at recommended intervals.

- Check spark plugs and ignition system for optimal performance.

Valve Timing And Performance

Proper valve timing is essential for the engine’s performance and preventing timing problems.

- Check valve clearance regularly.

- Ensure the camshaft and crankshaft are properly aligned.

Credit: www.justanswer.com

Frequently Asked Questions On Briggs And Stratton Timing Problems

Can You Adjust The Timing On A Briggs And Stratton Engine?

Yes, you can adjust the timing on a Briggs and Stratton engine using a timing light and wrenches.

What Is The Most Common Reason Why A Briggs & Stratton Small Engine Wont Run Correctly?

The most common reason a Briggs & Stratton engine won’t run correctly is due to stale fuel, dirt, or debris causing problems. If the equipment is stored with untreated gas, it can lead to engine damage. Regular maintenance is crucial to prevent these issues.

What Can Cause Surging On A Briggs And Stratton Motor?

Surging on a Briggs and Stratton motor can be caused by issues with engine timing or dirty fuel. Adjusting the timing with a timing light can help resolve the problem. Check for stale fuel and debris in the engine as well.

Conclusion

If you’re facing Briggs and Stratton timing problems, don’t fret. There are solutions available to help you align your engine’s timing gears and adjust the timing with the right tools. Stale fuel, dirt, and debris are common causes of engine issues, so make sure to address those as well.

Troubleshooting small engine problems can be a bit tricky, but with the right knowledge and guidance, you’ll be able to fix any timing issues that may arise. Keep your engine running smoothly and efficiently with proper timing adjustments.