Troubleshooting Briggs and Stratton carburetor issues involves identifying symptoms like sputtering starts and stalls.

This can indicate whether the problem requires cleaning or deeper adjustments.

What Are the Signs of a Carburetor Problem in a Briggs and Stratton Engine?

Recognizing carburetor problems in a Briggs and Stratton engine includes signs like trouble starting or uneven engine performance. Look for these indicators:

- The engine might be hard to start or not start at all, suggesting a clogged carburetor or incorrect air-fuel mix.

- The engine may start but then stop suddenly during use, which could mean the carburetor isn't providing a steady fuel mixture.

- Using more fuel than normal without increased use suggests the carburetor might be giving too much fuel, causing inefficient fuel use.

How Do I Clean the Carburetor on My Briggs and Stratton Engine?

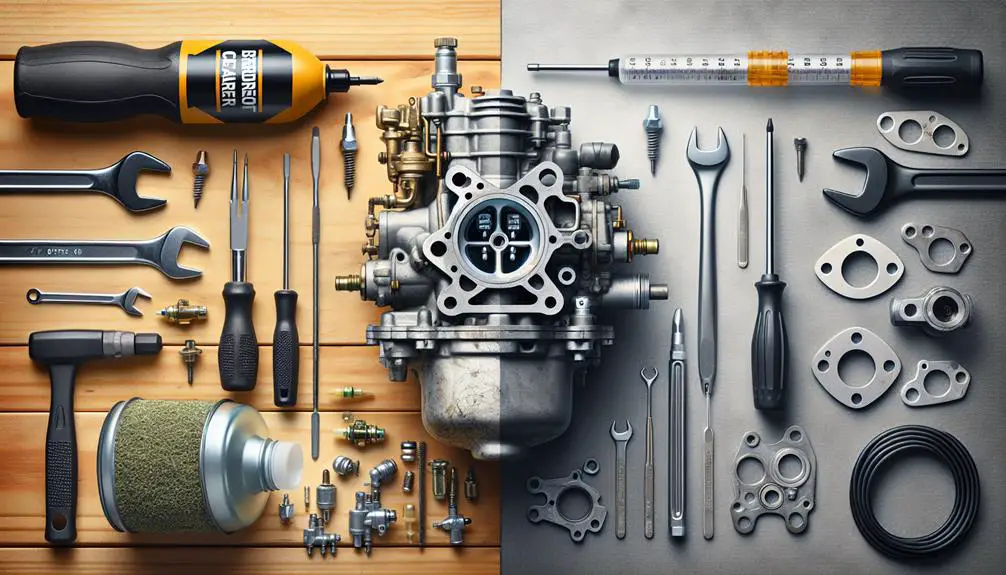

To clean the carburetor on your Briggs and Stratton engine, follow these steps. First, gather carburetor cleaner, a screwdriver, and a small wire brush or toothbrush. Make sure the engine is off and cool.

Then:

- Remove the air filter housing by unscrewing it to access the carburetor.

- Use the screwdriver to detach the carburetor from the engine. Remember how it's set up for reassembly.

- Spray carburetor cleaner inside and outside the carburetor, focusing on the jets and float bowl. Use the brush to remove hard deposits.

After cleaning, reassemble everything in the opposite order, ensuring tight fittings to prevent leaks.

Why Won't My Briggs and Stratton Engine Start?

Your Briggs and Stratton engine mightn't start for several reasons. Here are the main things to check:

- Fuel Level and Quality: Make sure there's enough new fuel in the tank. If the fuel is old or bad, replace it with new fuel.

- Spark Plug Condition: Check the spark plug for damage or dirt. Clean it if dirty, or replace it if damaged or old.

- Air Filter Clogging: Look at the air filter. If it's dirty, clean or replace it to allow air into the carburetor.

If these checks don't fix the problem, the issue might be with the carburetor, ignition system, or engine compression. These problems are more complex, and you might need to do further troubleshooting or get professional help.

Regular maintenance helps prevent these issues and keeps your engine running well.

Can I Adjust the Carburetor on My Briggs and Stratton Engine Myself?

Yes, you can adjust the carburetor on your Briggs and Stratton engine yourself.

Ensure you have basic mechanical knowledge, follow the correct steps, refer to your engine's manual or an online guide specific to your model, and work cautiously.

Step-by-step instructions for basic adjustments

Step 1:

Ensure your engine is cool before beginning any adjustments. Gather the necessary tools, including a flathead screwdriver, which will be used for most adjustments.

Step 2:

Locate your Briggs and Stratton carburetor's main adjustment screw. This screw is often found on the side of the carburetor and can be identified by its spring-loaded mechanism.

Step 3:

Start your engine and allow it to warm up for a few minutes. It's important to let the engine reach its operating temperature as adjustments to a cold engine may not be accurate.

Step 4:

After the engine has warmed up, turn it off before proceeding with any adjustments.

Step 5:

Gently turn the main adjustment screw clockwise until it's lightly seated. It's crucial to be gentle to avoid damaging the screw.

Step 6:

Turn the screw counterclockwise 1 1/2 turns. This will be your starting point for making the necessary fine-tuning adjustments.

Step 7:

Restart your engine. If the engine runs rough or stalls, further adjustments will be needed.

Step 8:

If the engine sounds sluggish, turn the screw clockwise to lean the fuel mixture. If the engine stalls or sounds uneven, turn the screw counterclockwise to enrich the fuel mixture. Make these adjustments in small increments, ideally no more than 1/8 of a turn at a time, until the engine runs smoothly.

When to call a professional for help

Seek professional help if troubleshooting fails.

If repeated troubleshooting attempts don't fix your Briggs and Stratton engine issues, contact a professional. Mechanical damage like cracks or severe corrosion in the carburetor necessitates expert repair or replacement.

Complex problems signaled by rough running, unusual noises, or excessive smoke after troubleshooting may indicate deeper engine issues affecting carburetor performance and require specialist knowledge.

If you're not confident in performing repairs or worried about causing damage, a professional technician can ensure a correct and efficient resolution.

How to Fix a Flooding Carburetor in a Briggs and Stratton Engine?

Step 1:

Turn off the fuel supply to prevent any additional fuel from entering the carburetor. Locate the fuel valve near the bottom of the fuel tank and switch it to the 'off' position. If your engine lacks a fuel valve, use a clamp to secure the fuel line and halt the flow of gasoline.

Step 2:

Remove the air filter to gain access to the carburetor. The air filter is typically enclosed in a plastic cover on the engine's side. You may need to unscrew a few bolts or release some snaps to take it off.

Step 3:

With the air filter removed, the carburetor will be exposed. Identify the bowl at the carburetor's base, which is generally secured by a bolt or a nut. Unfasten this bolt or nut with caution. Be prepared for fuel to start draining out, so have a container on hand to catch it.

Step 4:

Inspect the bowl for any dirt or debris that might cause the float to stick and result in flooding. Use carburetor cleaner to clean the bowl thoroughly and ensure the float moves freely in its range. If the float shows signs of damage, it will require replacement.

Step 5:

Reassemble the carburetor by putting the bowl back in place and securing it with the bolt or nut. Make sure everything is tightened and properly fitted.

Step 6:

Reattach the air filter and ensure it's securely in place by replacing the cover and fastening any bolts or snaps.

Step 7:

Turn the fuel supply back on by adjusting the fuel valve to the 'on' position or removing the clamp from the fuel line.

Step 8:

Attempt to start the engine. It should now initiate more smoothly and operate without the previous flooding issue.

What Causes a Briggs and Stratton Carburetor to Leak Gas?

Several factors can cause a Briggs and Stratton carburetor to leak gas. These include a loose fuel line, a damaged carburetor bowl, worn out gaskets or seals, issues with the float needle, and cracks in the carburetor bowl.

It's important to fix these problems quickly to prevent fuel waste and safety hazards. To fix a gas leak, check and replace any damaged parts. Regular maintenance can help avoid these issues and keep the engine running efficiently.

When Should I Replace My Briggs and Stratton Carburetor?

To decide when to change your Briggs and Stratton carburetor, look for these signs:

- Constant Engine Problems: If after cleaning and adjusting the carburetor your engine still runs poorly, it might be time for a new one. Signs include the engine stalling, hard starts, or uneven idling even after trying to fix these issues.

- Damage: Check the carburetor for visible damage such as cracks, warping, or heavy rust. These signal that you need a new carburetor because they affect how well it works.

- Hard to Find Parts: As your Briggs and Stratton engine gets older, it might be harder to find spare parts for the carburetor. If parts are no longer made or are hard to get, think about getting a new carburetor. A new one can mean easier to find parts and better engine performance.

FAQs: Troubleshooting Briggs and Stratton Carburetor Issues

You've encountered common issues with your Briggs and Stratton carburetor and are looking for answers.

Whether your engine stops abruptly, you're unsure about the cleaning frequency, or you're debating between repair and replacement due to bad gas, we've got the insights you need.

Let's tackle these frequently asked questions together, ensuring your carburetor functions at its best.

What do I do if my engine runs fine then suddenly stops?

Immediately check for fuel in the tank.

Inspect fuel lines for clogs or leaks.

Clean the carburetor bowl of debris.

Ensure the air filter isn't clogged.

Addressing these issues can resolve sudden engine stops.

How often should I clean my carburetor?

Clean your carburetor annually for optimal engine performance. For frequent use or operation in dusty conditions, clean it more often.

Regular maintenance prevents starting difficulties, irregular idling, and performance drops, ensuring a smoother running engine.

Can bad gas cause carburetor problems?

Yes, bad gas can cause carburetor problems by leaving residues that clog jets and passages, leading to engine issues like rough running or starting difficulties.

Always use fresh, high-quality gasoline to avoid these problems.

Is it better to repair or replace a malfunctioning carburetor?

Repair your carburetor if issues are minor and cost-effective, like clogged jets or sticky floats.

Replace it if there's significant damage, it's old, or parts are scarce, as a new one guarantees reliability and may include a warranty.

Conclusion

Fixing the carburetor problems in your Briggs and Stratton engine isn't too hard. You now know what signs to look for, how to clean and adjust the carburetor by yourself, and how to fix bigger problems like when it floods or leaks gas.

Remember, keeping it well-maintained is important. If nothing works, it might be time to get a new one. If you have more questions, feel free to learn more about fixing these issues. You can do it!